Opening a new era of intelligent welding! Jiangsu Beiren's teaching-free robot intelligent welding system is officially released!

With the introduction of the "14th Five-Year Plan for the Steel Structure Industry and the Vision for 2035", the goal of "by 2035, the application of steel structure buildings will reach the level of moderately developed countries, and the use of steel structures will reach more than 200 million tons per year" has become clearer, and the steel structure industry has also accelerated its transformation to automation and intelligence.

At present, the steel structure industry has diversified products, large output, complex structures, and different sizes. The traditional teaching programming method is difficult to be widely used. At the same time, companies in the industry generally face the dilemma of "difficulty in recruiting and retaining people", and the shortage of skilled workers has become an important factor restricting production efficiency and quality.

In response to the above-mentioned industry pain points, Jiangsu Beiren, relying on its deep accumulation in the field of intelligent manufacturing, has successfully launched a teaching-free robot intelligent welding system through independent research and development to meet the urgent needs of steel structure, shipbuilding and other industries for cost reduction, quality improvement and efficiency improvement.

Product Advantages

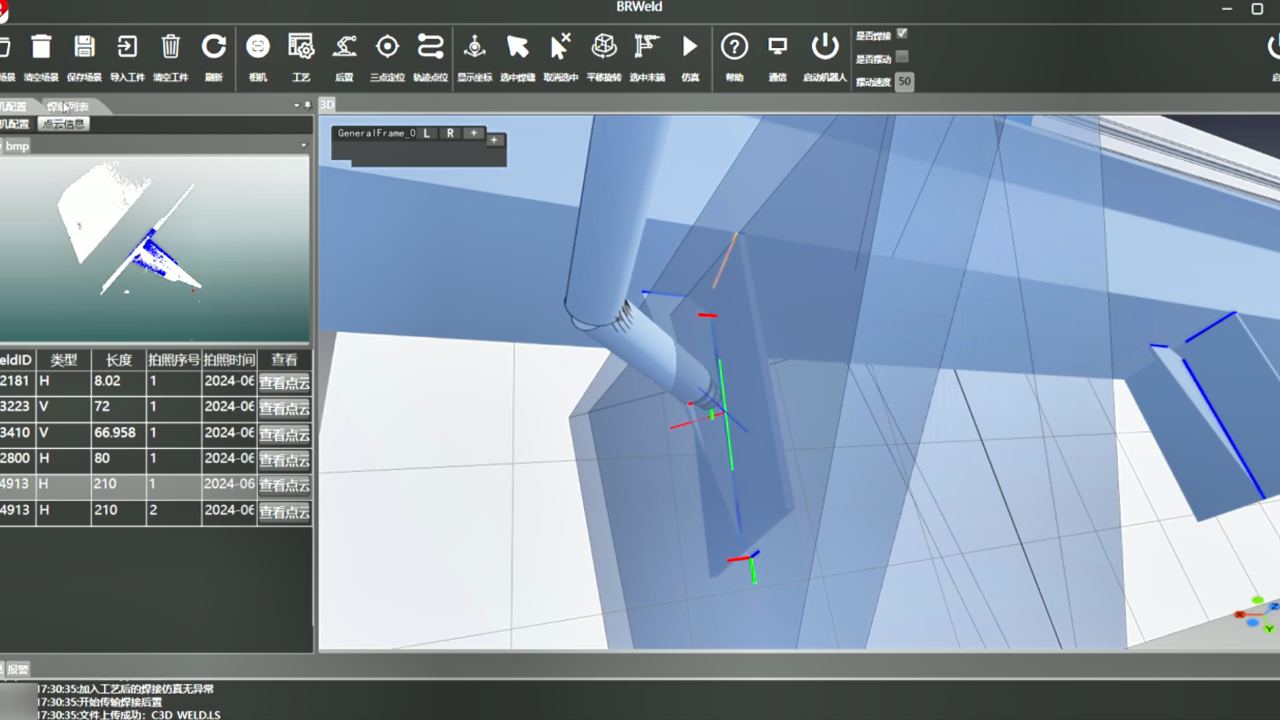

Jiangsu Beiren's teaching-free robot intelligent welding system has richer skills, more outstanding intelligence, and more flexible functions. It integrates the welding process expert library BR-iWeld, visual fusion perception and intelligent trajectory planning system, and automatically generates the optimal process parameters and welding procedures. The product is divided into two forms: upright and inverted, and the length of the ground rail can be customized according to customer needs.

Programming without teaching

Get rid of manual teaching, no need for positioning tooling

Welding process expert library BR-iWeld

Replace senior welders and match the optimal welding parameters

Good system compatibility

Applicable to various node types such as purlin support plates, end plates, rib plates, etc.

Stable welding quality

Optimal equipment configuration + industry KnowHow

Easy to operate

You can quickly master the system even if you have “0” foundation

High return on investment

Recover investment costs in about 1.5 years and achieve continuous cost reduction and efficiency improvement

BR-iWeld

Jiangsu Beiren's teaching-free robot intelligent welding system uses the welding process expert library BR-iWeld to achieve high-quality welding.

Based on the welding process database, BR-iWeld applies AI technology to simulate the thinking and knowledge of welding experts, conduct decision analysis, and automatically infer the required welding process parameters. The welding process data in the system can be deposited as corporate assets.

Service and Support

Jiangsu Beiren provides the system with the full process service of "pre-sales-order-delivery-after-sales".

Pre-sales

Provide product demonstrations and technical consultation, and customize the best solutions according to customer needs

Order

Provide detailed quotations, clear product options and purchase guides; professional customer service support, answer questions during the order process

Delivery

Products undergo strict quality inspections, and professional personnel provide customers with product use and maintenance training

After-sales

Establish an exclusive customer service group to respond to problems encountered during use at any time; collect customer feedback, and continuously upgrade products and optimize services

400-1016-959

400-1016-959 Map

Map